There are five Types of Circuit Breakers and In this article we will speak about

- Air break circuit breaker

- Air-Blast Circuit-Breaker

- Bulk Oil and Minimum Oil Circuit Breaker

- Sulphur Hexafluoride (SF6) Circuit Breaker and SF6 Insulated Metalclad switchgear

- Vacuum circuit breaker

Introduction (Sulphur Hexafluoride (SF6) Circuit Breaker)

Sulpher hexafluoride (SF6) is an inert, heavy gas having good dielectric and arc extinguishing properties. The dielectric strength of the gas increases with pressure and is more than that of dielectric oil at pressure of 3 kgf/cm2. This gas is now being very widely used in electrical equipment like high voltage metal enclosed cables; high voltage metal clad switchgear, capacitors, circuit breakers, current transformers, bushings, etc. This gas liquefies at certain low temperatures, the liquefaction temperature increases with pressure. This gas is commercially manufactured in many countries and is now being extensively used by electrical industry in Europe, U.S.A. and Japan.

Several types of SF6 circuit breakers have been developed by various manufacturers in the world, for rated voltage from 3.6 to 760 KV. However, at present they are generally preferred for voltages above 72.5 KV.

SF6 gas insulated metal clad switchgear comprises factory assembled metal clad, substation equipment like circuit breakers, isolators, earthing switches, bus bars, etc. These are filled with SF6 gas . Such sub-stations are compact and are being favoured in densely populated urban areas.

Sulphur hexafluoride gas is prepared by burning coarsely crushed roll sulphur in the fluorine gas, in a steel box, provided with staggered horizontal shelves, each bearing about 4 kg of sulphur. The steel box is made gas-tight. The gas thus obtained contains other fluoride such as S2F10 , SF4and must be purified further. SF6 gas is generally supplied by chemical firms. The cost of gas is low if manufactured on a large scale.

• The gas is transported in liquid from in cylinders. Before filling the gas, the circuit breaker is evacuated to the pressure of about 4 mm of mercury so as to remove the moisture and air. The gas is then filled in the circuit breaker. The gas can be reclaimed by the gas handling unit

There are two types of SF6 circuit breakers:

- Single pressure puffer type SF6 circuit • In which the entire circuit breaker is filled with SF6 gas at single pressure ( 4 to 6 kgf/cm2) . The pressure and gas flow, required for arc extinction, is obtained by piston action.

- Double pressure type SF6 circuit breaker • In which the gas from high pressure system is released into low pressure system over the arc during the arc quenching process. This type has been superseded by puffer type.

Properties of SF6 Gas

Sulphur hexafluoride (SF6) gas has good dielectric and arc extinguishing properties. The dielectric strength of the gas increase with pressure and is more than that of the dielectric oil at high pressures. SF6 is now very widely used in electrical equipments like high voltage metal enclosed cables, high voltage metal clad switchgear, capacitors, circuit breakers, current transformers, high voltage bushing, etc.

Sulphur hexafluoride gas is of low cost if manufactured on a large scale. It is transported in liquid from cylinders. Before filling the gas, the circuit breaker is evacuated to the pressure of about 4mm of mercury so as to remove the moisture and air. The gas is then filled

1 Physical properties of SF6 gas

- Colorless.

- Odorless.

- Nontoxic. Pure SF6 gas is not harmful to health. However, impure SF6 gas contains toxic impurities.

- Inflammable.

- Stat: gas at normal temperature and pressure.

- Density : heavy gas with density 5 times that of air at 20 ° C and atmospheric pressure.

- Liquefaction of SF6 Gas

Liquefaction of SF6 Gas

The gas starts liquefying at certain low temperatures. The temperature of liquefaction depends on pressure. At 15 kgf/cm2the gas starts liquefying at 10 ° C . Hence this gas is not suitable for pressure above 15 kgf/cm2

The temperature at which the SF6 gas changes to liquid state depends on the pressure. With higher pressure, the temperature increases. To avoid the liquefaction of SF6 gas. the temperature of SF6 should be maintained above certain value. For atmospheric pressure, SF6 gas starts liquefying at a temperature of about 10 ° C. Hence thermostatically controlled heaters are provided, which maintain the gas temperature above about 16 ° C in case of high pressure system.

Heat Transferability

The heat transferability of SF6 gas is 2 to 2.5 times that of air at same pressure. Hence for the equal conductor size, the current carrying capacity is relatively more.

Enthalpy

Heat content property at temperature below 6000 ° K is much higher than nitrogen. This assists cooling of arc space after current zero, due to continuous removal of heat from the contact space by the surrounding gas.

Low arc time constant

The time constant of the medium is defined as "the time between current zero and the instant the conductance of contact space reaches zero value". Due to the electro negativity of SF6 gas the arc time constant of SF6 gas is very low and the rate of dielectric strength is high. Hence SF6 circuit breakers are suitable for switching condition. involving high rate of rise of TRV.

2 Chemical properties of SF6 Gas

- Stable up to 500 ° C.

- Inert. The chemical inertness of this gas is advantageous in switchgear. The life of metallic part, contacts is longer in SF6 gas. The components do not get oxidized or deteriorated. Hence the maintenance requirements are reduced. Moisture is very harmful to the properties of the gas. In the presence of moisture, hydrogen fluoride is formed during arcing which can attack the metallic and insulating parts in the circuit breaker.

- Electronegative gas.

- Does not react with structural material up to 500°C.

- Products of decomposition. During arc extinction process SF6 is broken down to some extent intoSF4, SF2. The products of decomposition recombine upon cooling to form the original gas. The remainder is removed by filters containing activated alumina ( AL2O3) Loss factor is small. The products of decomposition are toxic and attack certain structural materials.

- The metallic fluorides are good dielectric materials hence are safe for electrical equipment.

- Moisture content in the gas, due to influx from outside, present a various problems in SF6 circuit breakers. Several failures have been reported recently due to this cause.

3 Dielectric properties of SF6 Gas

Dielectric strength of SF6 gas atmospheric pressure is 2.35 times that of air, it is 30% less than of dielectric oil used in oil circuit breakers. • At higher pressure the dielectric strength of the gas increases. At pressure about 3 kgf/cm2the dielectric strength of SF6 gas is more than that of dielectric oil. This property permits smaller clearance and small size of equipments for the same KV.

The breakdown voltage in SF6 gas depends on several aspects such as electrode configuration, roughness of electrodes, distribution of electric field, vicinity of insulating supports, moisture, wave shape etc. Other parameters remaining constant, the breakdown voltage in SF6 increases with pressure. The gas follows paschen's law which states that "in uniformly distributed electric field, the breakdown voltage (Vb) in a gas is directly proportional to the product of gas pressure (p) and electrod gap (d)"

Vb∝pd

The pressure at which the breakdown voltage starts reducing is called 'Critical pressure'. The dielectric strength at pressure between 2-3 kgf/cm2 is high.

Hence this pressure range preferred in SF6 insulated metal enclosed switchgear. However, in circuit breaker compartment, the pressure of the order of is kgf/cm2 preferred for arc quenching process.

Hence this pressure range preferred in SF6 insulated metal enclosed switchgear. However, in circuit breaker compartment, the pressure of the order of is kgf/cm2 preferred for arc quenching process.

Rough electrode surface reduces the breakdown voltage with rough surface the ionization starts earlier near the sharp points on conductors. Hence conductor surfaces should be smooth

The conductor in SF6 insulating equipment is supported on epoxy or porcelain insulators. The flashover invariably takes place along the surface of the support insulators. The breakdown can occur at extremely low values if the insulators support is covered by moisture and conducting dust. Hence the insulators should be extremely clean and should have anti-tracking properties.

The breakdown is initiated at sharp edges of conducting parts and parts having maximum stress concentration.

The limiting value of breakdown stress is of the order of 20 P KV/cm for pure SF6 and P is pressure of gas in kgf/cm2 Good stress distribution is very important in SF6 insulated equipment.

The breakdown value depends on the wave-shape characterized by peak value, wave front, wave-tail, polarity in case of impulse wave. Voltage withstand value reduces with increase in steepness and increase in duration of the wave. Negative polarity is generally more severe than positive.

SF6 gas maintain high dielectric strength even when diluted by air (Nitrogen). 30% SF6 + 70 % of air, by volume, has a dielectric strength twice that of air (at the same pressure). Below 30% by volume, the dielectric strength reduces quickly

Arc Extinction in SF6 Circuit Breaker

High voltage circuit breaker with SF6 gas as the insulation and quenching medium have been in use throughout the world for more than 30 years. This gas is particularly suitable because of its high dielectric strength and thermal conductivity.The current interruption process in a high voltage circuit breaker is a complex matter due to simultaneous interaction of several phenomena. When the circuit breaker contacts separate, an electric arc will be established, and current will continue to flow through the arc. Interruption will take place at an instant when the alternating current

When a circuit breaker is tripped in order to interrupt a short circuit current, the contact parting can start anywhere in the current loop. After the contacts have parted mechanically, the current will flow between the contacts through an electric arc, which consists of a core of extremely hot gas with a temperature of 5,000 to 20.000 K. This column of gas is fully ionized (plasma) and has an electrical conductivity comparable to that of carbon. When the current approaches zero, the arc diameter will decrease. with the cross section approximately proportional to the current. In the vicinity of zero passage of current, the gas has been cooled down to around 2.000 K and will no longer be ionized plasma, nor will it be electrically conducting.

Two physical requirements (regimes) are involved :

- Thermal regime : The hot arc channel has to be cooled down to a temperature low enough that it ceases to be electrically conducting.

- Dielectric regime : After the arc extinction, the insulating medium between the contacts must withstand the rapidly increasing recovery voltage. This recovery voltage has a transient component (transient recovery voltage, TRV) caused by the system when current is interrupted.

Thermal regime

The thermal regime is especially critical at short line fault interruption. The circuit parameters directly affecting this regime are the rate of decrease of the current to be interrupted (di/dt) and the initial rate of rise of the transient recovery voltage (dv/dt) immediately after current zero. The higher the values of either of these two parameters, the more severe the interruption is. A high value of (di/dt) results a hot arc with a large amount of stored energy at current zero, which makes interruption more difficult. High values of (dv/dt) will result in an increase of the energy to the post

These exists a certain inertia in the electrical conductivity of the arc. When the current approaches zero, these is still a certain amount of electrical conductivity left in the arc path. This gives rise to what is called a "post-arc current". With amplitude up to a few A. Whether or not interruption is going to be successful is determined by a race between the cooling effect and the energy input in the arc path by the transient recovery voltage. When the scales of the energy balance tip in favour of the energy input the circuit breaker will fail thermally. The thermal interruption regime for SF6 circuit breakers corresponds to the period of time starting some µs before current zero, until extinguishing of the post arc current, a few s after current zero.

Dielectric regime

When the circuit breaker has successfully passed the thermal regime, the transient recovery voltage (TRV) between the contacts rises rapidly and will reach a high value. For example, in a single unit 245 KV circuit breaker, the contact gap may be stressed by 400 KV or more 70 to 200 µs after the current zero.

In the dielectric regime the extinguishing/ isolating medium is longer electrically conducting, but it still has a much higher temperature than the ambient. This reduces the voltage withstand capacity of the contact gap. The stress on the circuit breaker depends on the rate of rise and the amplitude of the TRV.

The withstand capability of the contact gap must always higher than the transient recovery voltage otherwise a dielectric re-ignition will occur (dielectric failure). This requires an extremely high dielectric withstand capability of the gas, which is still rather hot and therefore has low density.

The arc extinction process, in SF6 CB, is different from that in air blast CB. During the arcing period, SF6 gas is blown axially along the arc. The gas removes from the arc by axial convection and radial dissipation. As a result, the arc diameter reduces during the decreasing mode of the current wave. The diameter becomes small during current zero

Due to its electro negativity and low arc time constant, the SF6 gas regains its dielectric strength rapidly after the final current zero, the rate of rise of dielectric strength is very high and the time constant is very small.

The arc extinguishing properties of SF6 gas was pointed out in 1953. The research pointed out that SF6 is a remarkable medium for arc extinction. The arc extinguishing properties are improved by moderate rates of forced gas flow through the arc space.

Plain break contacts drawn apart, (AC arcs), in SF6 can interrupt about 100 times more current than in air at

The basic requirement in arc extinction is not primarily the dielectric strength, but high rate of recovery of dielectric strength. In SF6 gas, the electrons get attached with molecules to become ions. Thereby, the dielectric strength is quickly regained. Problems connected with current chopping are therefore minimized.

In SF6 CB, The gas is made to flow from a high pressure zone to a low pressure zone through a convergent-divergent nozzle. The mass flow is a function of the nozzle-throat diameter, the pressure ratio, and the time of flow. the nozzle is located such that the flow of gas covers the arc . The gas

The gas flow attains almost supersonic speed in the divergent portion of the nozzle., thereby the gas takes away the heat from the periphery of the arc, causing reduction in the diameter of the arc. Finally, the arc diameter becomes almost zero at current zero and the arc is extinguished. The arc space is filled with fresh SF6gas and the dielectric strength of the contact space is rapidly recovered due to the electro-negativity of the gas. The single flow pattern (Fig. 23a) and double flow pattern (Fig. 23b) are used for arc extinguishing in single-pressure puffer type and double-pressure type SF6 circuit breakers.

(b) Double axial flow pattern

Figure 23 Arc extinction in gas flow circuit breakers (Gas flows from high pressure to low pressure)

single pressure puffer type circuit breaker, with single flow quenching medium

When breaker is fully closed, the pressure in the puffer cylinder is equal to that outside the cylinder. • During opening stroke, puffer cylinder and moving contact tube start moving.

Gas gets compressed within puffer cylinder. • After a certain travel, contact separates and arc is drawn.

However, compressed gas flows from higher pressure to lower pressure through the nozzle.

Single Pressure Puffer Type SF6 Circuit Breaker

- This type of circuit breakers employs the principle of puffer action, illustrated above. Figure 24(a) illustrates the fully closed position of the cylinder.

Fiure 24 Puffer action rincile

• The moving cylinder is coupled with the movable conductor against the fixed piston, and there is a relative movement between the moving cylinder and the fixed piston.

• The gas is compressed in the cavity.

• This trapped gas is released through the nozzle, during arc extinction process.

• During the travel, of the moving contact and the movable cylinder, the gas puffs over the arc and reduces the arc diameter by axial convection and radial dissipation.

• At current zero, the arc diameter becomes too small and the arc gets extinguished

• The puffing action continues for some time, even after the arc extinction, and the contact space is filled with cool, fresh gas.

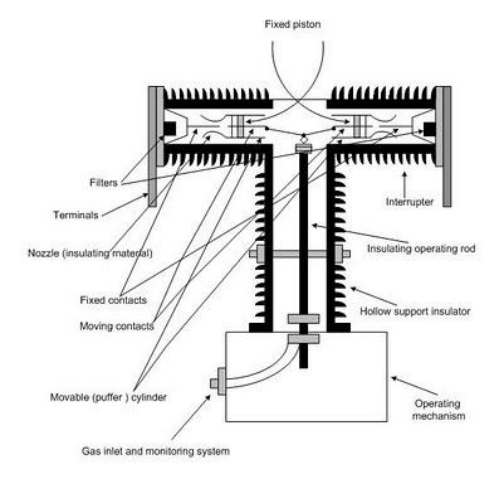

• Figure 25 illustrates the configuration of a 245 KV/420 KV single-pressure SF6 circuit breaker. The two interrupters are mounted on the hollow support insulators. The operation mechanism, installed at the base of the insulators, is linked with the movable contact in the interrupter, by means of insulating operating rod and a link mechanism.

Figure 25

One pole of 245 KV puffer type SF6 circuit breaker

• The circuit breaker is filled with SF6 gas at a pressure of about 5 kgf/cm2. During the opening operation, the operating rod is pulled downwards by the operating mechanism. the link mechanism converts the vertical motion into horizontal motion. The contact and the movable cylinder, in the interrupter, are moved against the fixed position.

• Break-time up to 3 cycles can be achieved by puffer principle described above. For achieving 2 cycle break-time, differential position is used, in which the puffer cylinder and piston move in opposite directions, thus reducing total stroke and time of travel.

5.4.5 Merits and Demerits of SF6 Circuit Breaker • Outdoor EHV SF6 CB has less number of interrupters per pole than ABCB and MOCB. It is simple, less costly, maintenance free compact. • The gas is non-inflammable and chemically stable. The decomposition product are not explosive. Hence there is no danger of fire or explosions. • Same gas is re-circulated in the circuit. Hence requirement of SF6 gas is small in the long run. No replacement is required for at least five years. • Ample overload margin. For the same size of conductors, the current carrying ability of SF6 CB is about 1.5 times that of ABCB because of superior heat transferability of SF6 gas.

• The breaker is silent and does not sound, like ABCB, during operation.

• The sealed construction avoids the contamination by moisture, dust, sand, etc.

• No cost for compressed air system as in ABCB. • Maintenance required is minimum. The breaker may need maintenance once in four to ten years. • Ability to interrupt low and high fault currents, magnetizing currents, capacitive currents, without excessive over voltage. Sf6 gas CB can perform the various duties like clearing short line faults, opening unloaded transmission lines, capacitor switching, transformers, reactor switching. etc. much smoothly

• The breaker is silent and does not sound, like ABCB, during operation.

• The sealed construction avoids the contamination by moisture, dust, sand, etc.

• No cost for compressed air system as in ABCB. • Maintenance required is minimum. The breaker may need maintenance once in four to ten years. • Ability to interrupt low and high fault currents, magnetizing currents, capacitive currents, without excessive over voltage. Sf6 gas CB can perform the various duties like clearing short line faults, opening unloaded transmission lines, capacitor switching, transformers, reactor switching. etc. much smoothly

• Short break time of 2 to 2.5 cycles.

• High electrical endurance, allowing at least 25 years of operation without reconditioning

• Possible compact solutions when used for GIS or hybrid switchgear.

• Integrated closing resistors or synchronized operations to reduce switching over voltages. • Reliability and availability.

• Low noise level.

• 5.4.6 Some Demerits of SF6 Circuit Breaker 1. Sealing problems arise due to the type of construction used. Special materials are necessary in construction. Imperfect joints lead to leakage of gas.

2. Arced SF6 gas is poisonous and should not be inhaled or let-out.

3. Influx of moisture in the system is very dangerous to SF6 gas circuit breakers.

4. The double pressure SF6 CB is relatively costly.

5.The internal parts should be cleaned thoroughly during periodic maintenance, under clean, dry environment.

6. Special facilities are needed for transporting the gas, transferring the gas, and maintaining the quality of the gas. The deterioration of quality of the gas affects the reliability of the SF6 circuit breaker.